Benefits

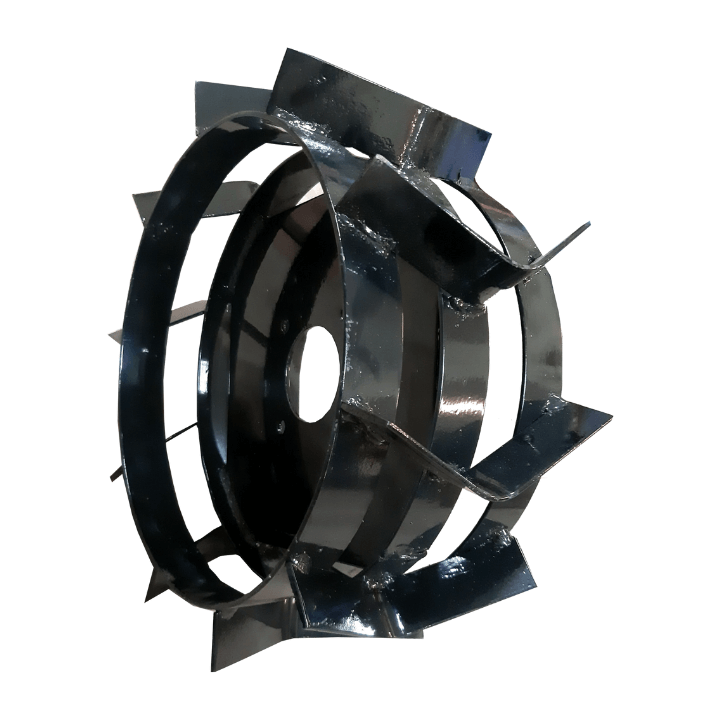

Much Better Traction on Field Soil

Iron wheels have deep lugs or cage patterns that grip the soil firmly, especially in clay, soft wet land, or muddy paddy fields. This prevents the tiller from spinning in place and helps it move forward smoothly during heavy tilling or ploughing.

2. Improved Stability and Control

Because iron wheels sit firmly on the ground and don’t slip as rubber wheels might, the tiller becomes more stable and easier to steer. This is especially important when working on uneven terrain or in heavier soils.

3. Increased Soil Penetration and Depth Control

The extra traction helps the blades or tilling tynes dig deeper into compact soil — meaning better soil preparation before sowing or planting.

4. Suitable for Wet or Paddy Fields

Special cage-style iron wheels are excellent for puddling and working in wet or waterlogged fields where regular wheels would struggle. They churn the saturated soil and help prepare it uniformly.

5. Durable and Long-Lasting

Iron wheels are made from solid metal designed to withstand hard farm use, rocks, roots, and other tough conditions — they typically last much longer than plain rubber wheels under heavy field work.

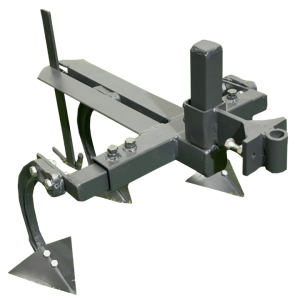

6. Better Performance in Tillage and Ploughing

With enhanced grip and balance, the tiller can pull attachments (like plough bottoms or ridgers) more effectively, reducing engine strain and fuel usage.

Other Practical Notes

Maintenance: Iron wheels can rust, so it’s good to clean and protect them periodically with anti-rust coating, especially if used in wet conditions.

Installation: Make sure the wheel shaft diameter matches your tiller’s axle (often ~23 mm) before purchase.

Pair Sets: Wheels are usually sold in pairs (left and right) and sometimes with tyre holder shafts to make mounting easier.